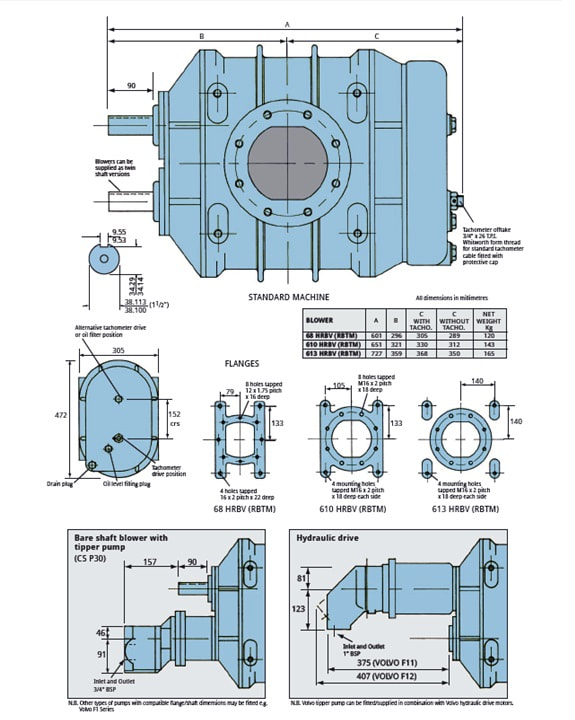

HRBV Truck Blowers

|

Design Features

The conservative load carrying capacity of the larger diameter bearings ensures an extended operating life. Timing gear life is also extended by a controlled lubrication system. The computer calculated impeller profiles ensure maximum volumetric efficiency with maximum absorbed power without sacrificing torsional rigidity. The high rigidity of the impeller and generous shaft diameter keeps stresses low. Gear and shaft strength is substantially increased by the use of slow taper mounted gears which do not need keyways for location. This also simplifies the setting of the gear wheels to obtain correct timing of the impellers, a feature that facilitates field maintenance. Precision ground and hardened steel gears are used to ensure smooth running and accurate timing of the rotating impellers. Specifically designed rotary oil seals are used in the gearcase. This feature eliminates maintenance associated with the use of lip seals. This range can now be supplied with oil lubricant at the drive end as well as the gear end and thus helps to simplify maintenance. This feature is particularly attractive where the blower is used in high ambient temperature conditions. Design and manufacture is in accordance with metric standards. |

Specification

» A range of 3 sizes » Impellers made from SG iron & cast with integral shafts » Precision ground spur gears, taper mounted onto the impeller shafts » High quality bearings for long operation life » Oil lubricated versions for increased service life and particularly suitable for operation higher ambient temperatures, the oil-lube HRBV is a natural progression on the original grease/oil lubricant version. Sizes and capacities » Capacities from 220 to 2300 m3/hr » Pressures to 1240 mbarg » Vacuums to 475 mbarg Applications » Truck mounting for vehicle tank extraction » Dry bulk conveying powders, animal feeds, etc. » Land based pneumatic conveying systems » Vacuum as well as positive pressure operation |

Performance

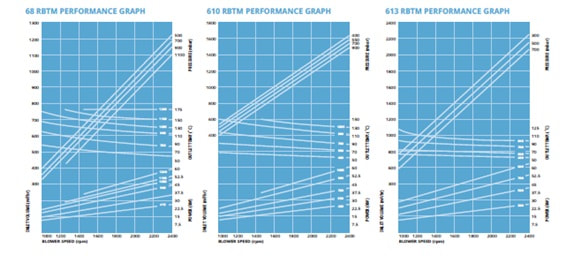

The graph and table show the performance as blowers. However all three sizes can operate as exhausters at vacuum up to 475mbar or combinations of pressure and vacuum.

The graph and table show the performance as blowers. However all three sizes can operate as exhausters at vacuum up to 475mbar or combinations of pressure and vacuum.

*The relief valve should be selected, set and maintained to pass all the volume delivered without the pressure at the outlet of the blower exceeding the above maximum pressure when the minimum recommended speed is that shown in the above table.

Caution: The bhp remains constant for any given impeller speed and outlet pressure. When selecting power take-off equipment, relate the bhp to the blower input shaft speed if a speed increasing gearbox is used. The torque increases in direct proportion to the blower gearbox ration.

Caution: The bhp remains constant for any given impeller speed and outlet pressure. When selecting power take-off equipment, relate the bhp to the blower input shaft speed if a speed increasing gearbox is used. The torque increases in direct proportion to the blower gearbox ration.